Veegoo fabrication solution

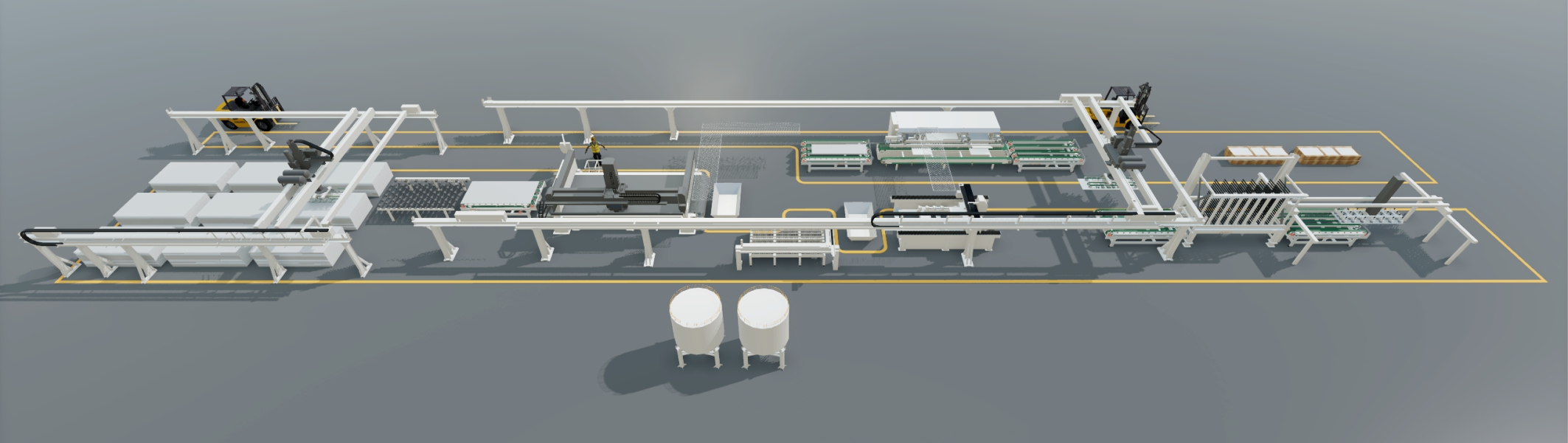

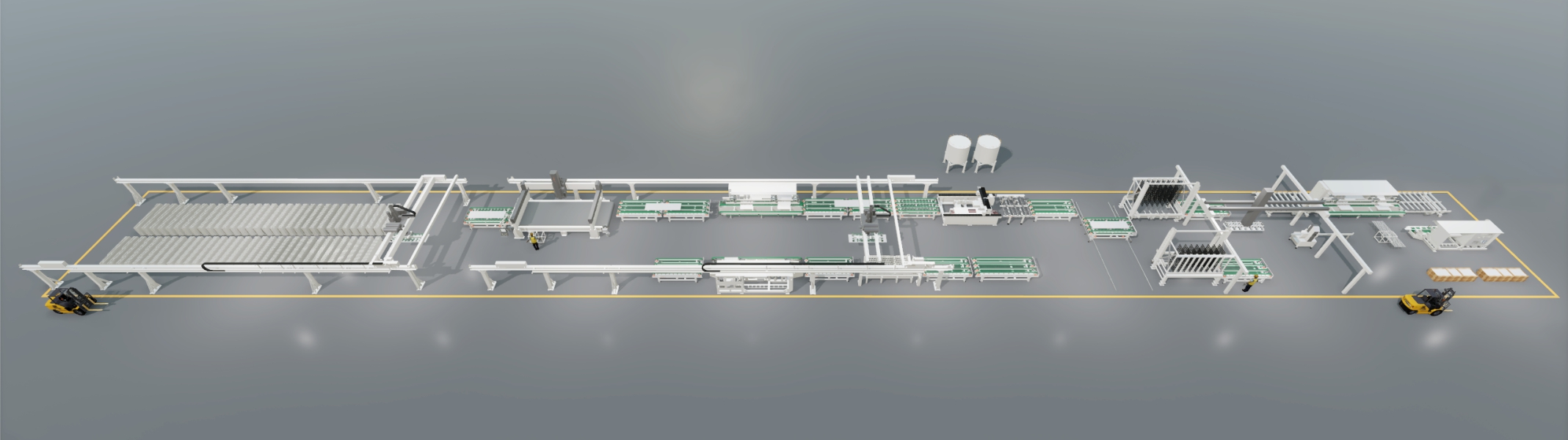

- Veegoo fabrication includes solutions for single machines and whole production line, to meet different requirements.

- Veegoo whole line solutions include Solar, Galaxy and Universe, capacity will be 8-10 orders/shift, 15-20 orders/shift and 40 orders/shift.

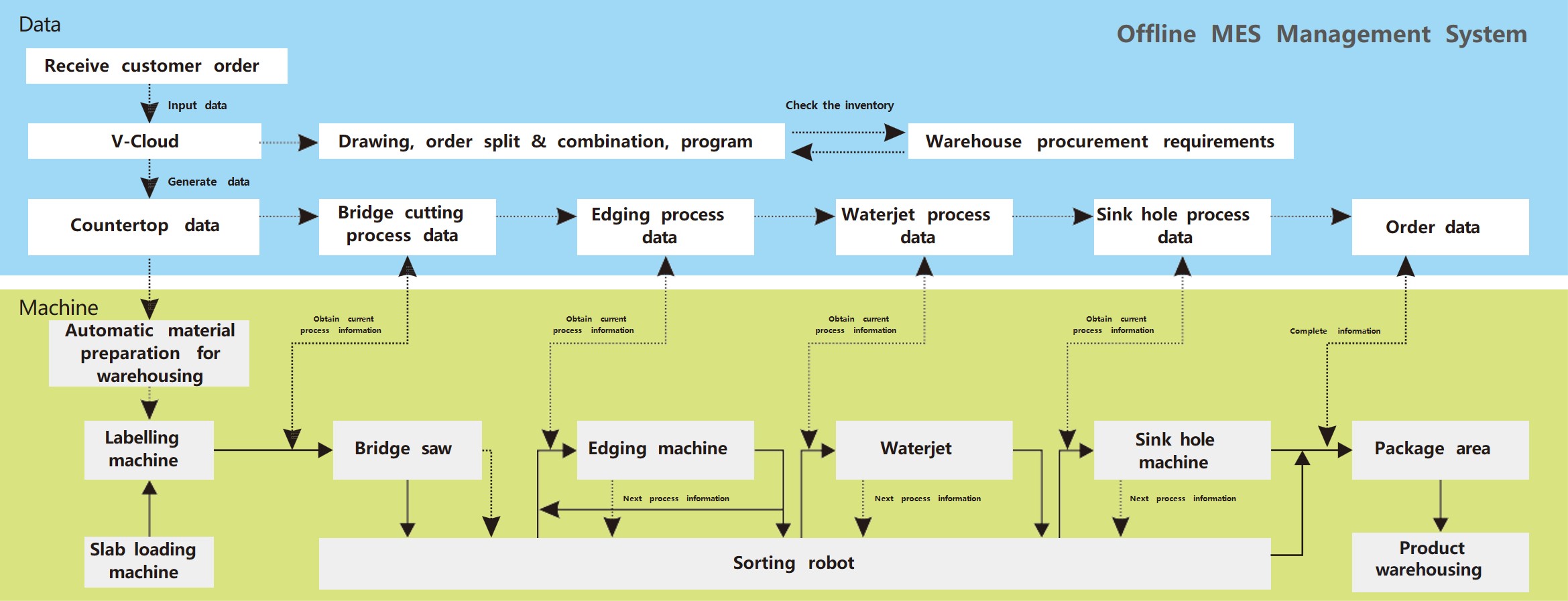

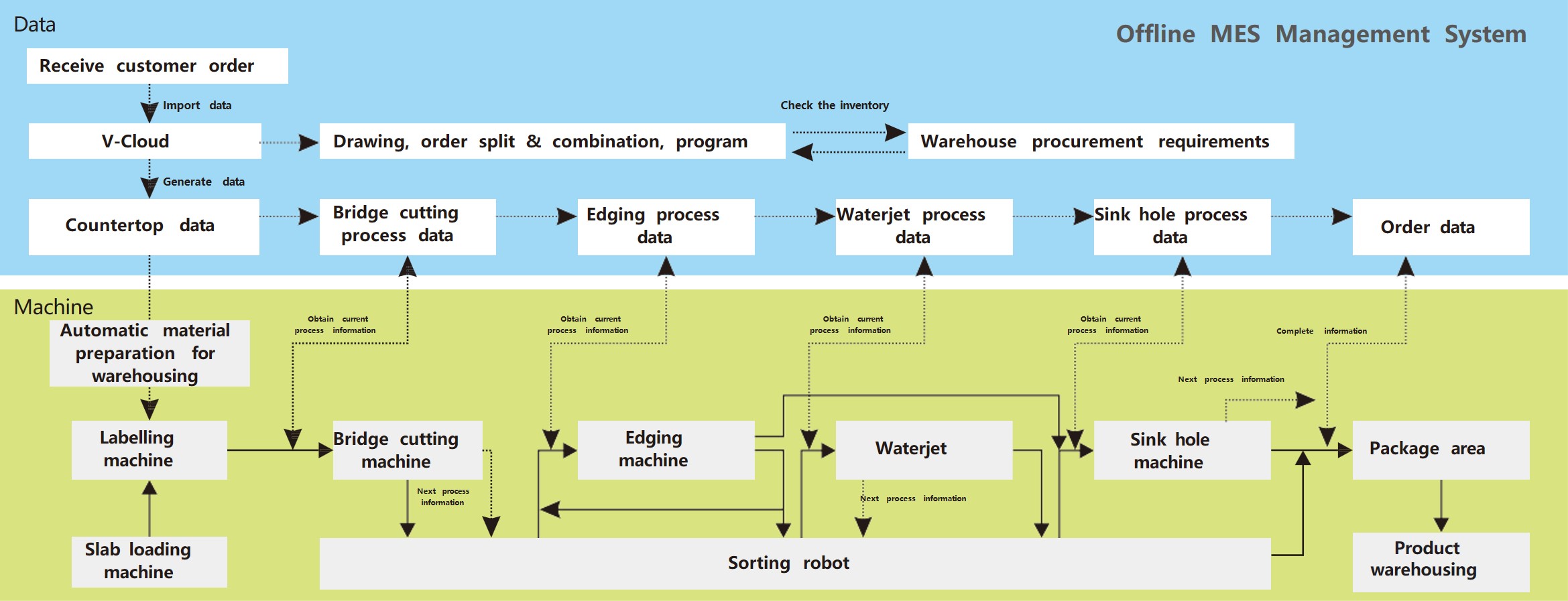

- Veegoo's intelligent countertop fabrication line revolutionizes the traditional single-machine workstation model by adopting a connected line working method. The line features a high level of automation, with automatic transmission of processing procedures and intelligent sorting and transfer, significantly reducing manual labor. Optimal equipment is used for each process.

- The entire line uses a self-developed platform system and MES system to achieve human-machine collaborative production.

- The production line is suitable for both stone and porcelain slab countertop fabrication, enhancing the versatility of the line.

- Information management is achieved through a software control system, which monitors and manages information in real time, improving production management and quality control.

- By adopting automatic programming combined with manual adjustment, the material yield rate is increased to 85-90%, reducing the generation of waste materials, which meets the requirements of green and environmental protection.

- From the platform system to the MES system, it can be highly customized according to customer needs.

- Equipped with a material preparation system, which can prepare materials in advance according to order.

- Equipped with a residual material management system, which prioritizes the selection of available residual materials during programming and material preparation to improve material yield.

Fabshop Solar

Fabshop Solar is a lightweight production line, which is suitable for small and medium-sized Fabshop. It establishes a complete connection mode that covers the entire process from sales, warehouses, design offices, production workshops to the finished products being dispatched out of the warehouse.

- The production line utilizes a self-developed platform system and MES system to achieve human- machine collaboration in production.

- The production line can fabricate both stone and porcelain slab.

- Information management is implemented through a software control system, enabling real-time monitoring and management of production line, enhancing production management and quality control levels.

- With intelligent program and manual adjustment, it can improve the output percentage and reduce waste material.

- Both the platform system and the MES system can be highly customized according to customer requirements.

Fabshop Galaxy

Fabshop Galaxy is a high-configuration production line, which is suitable for high-output Fabshop. It establishes a complete connection mode that covers the whole process from sales, warehouse, design office, production workshop to the delivery of finished products.

- The production line utilizes a self-developed platform system and MES system to achieve human- machine collaboration in production.

- The production line can fabricate both stone and porcelain slab.

- Information management is implemented through a software control system, enabling real-time monitoring and management of production line, enhancing production management and quality control levels.

- With intelligent program and manual adjustment, it can improve the output percentage and reduce waste material.

- Both the platform system and the MES system can be highly customized according to customer requirements.

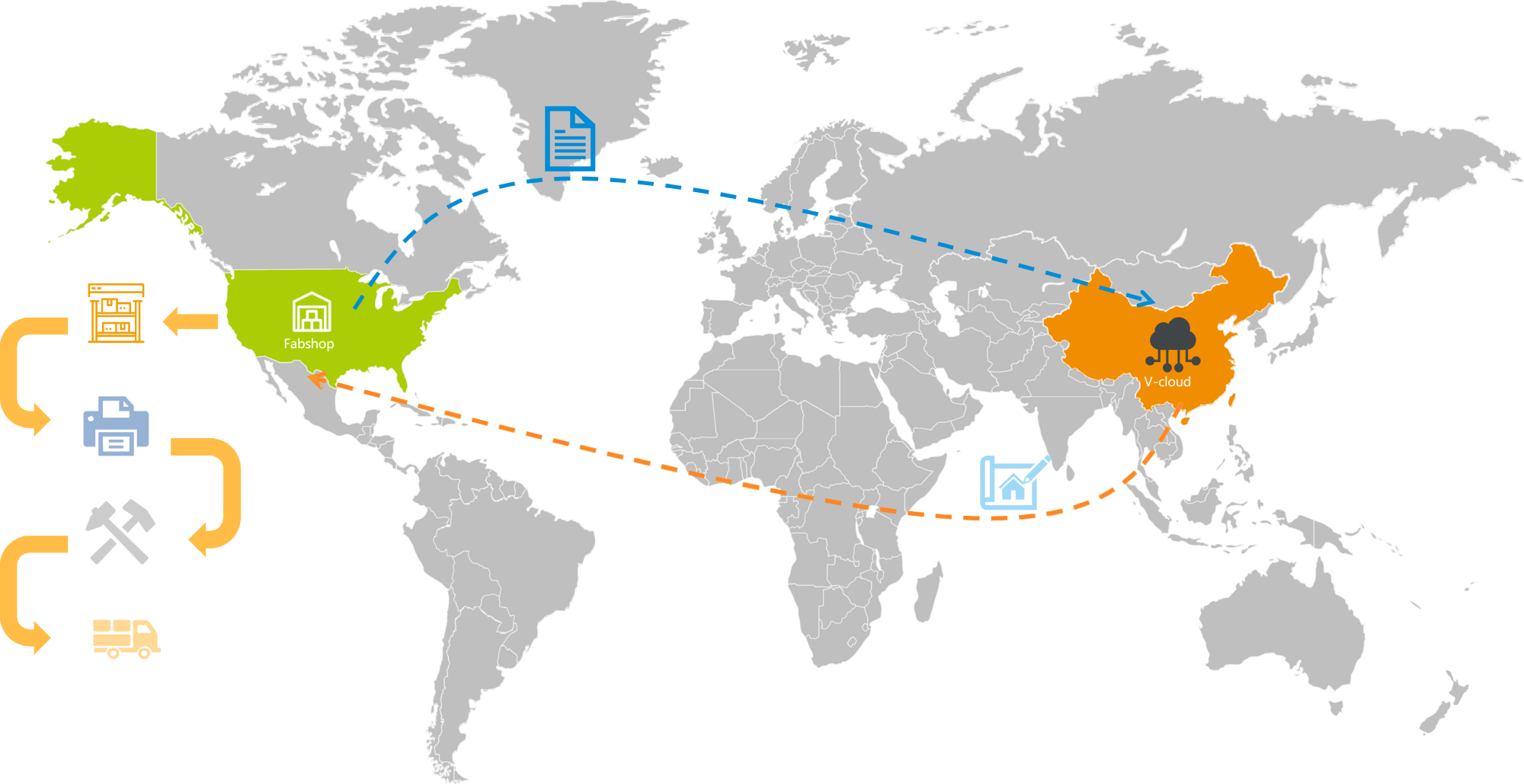

Remote drawing in the data center, order decomposition, production scheduling, and materials preparation information