Veegoo Fabrication Solution

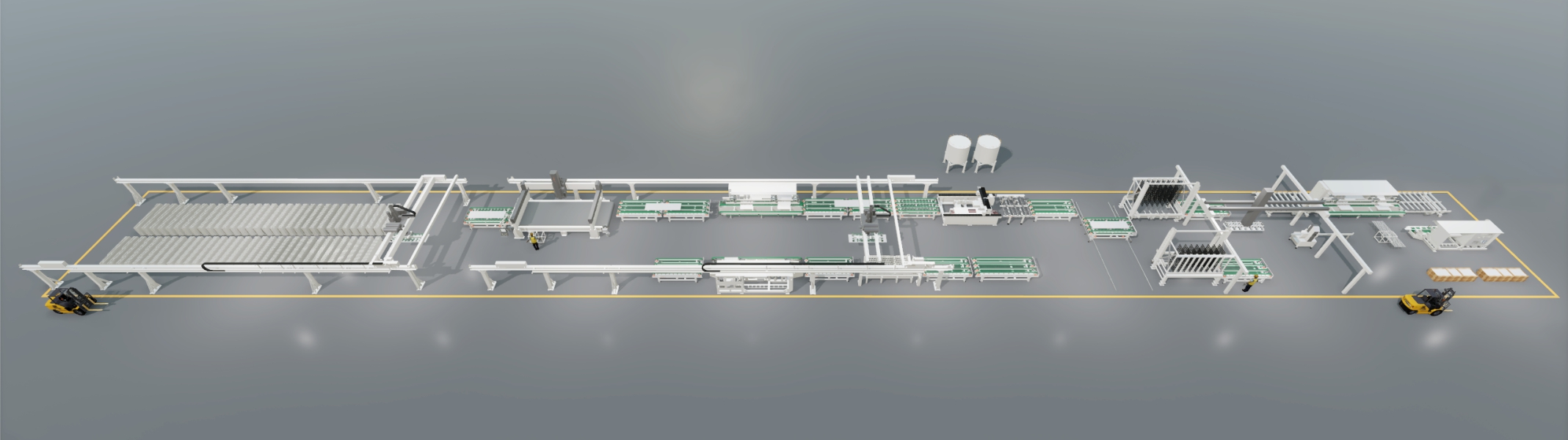

- Veegoo fabrication includes solutions for single machines and whole production line, to meet different requirements.

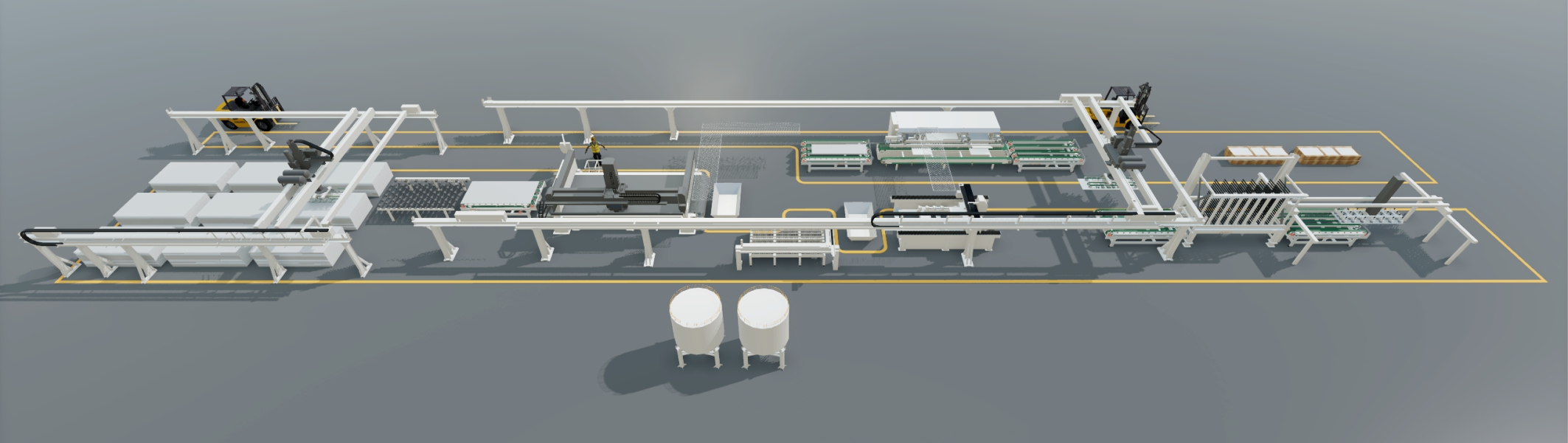

- Veegoo whole line solutions include Solar, Galaxy and Universe, capacity will be 8-10 orders/shift, 15-20 orders/shift and 40 orders/shift.

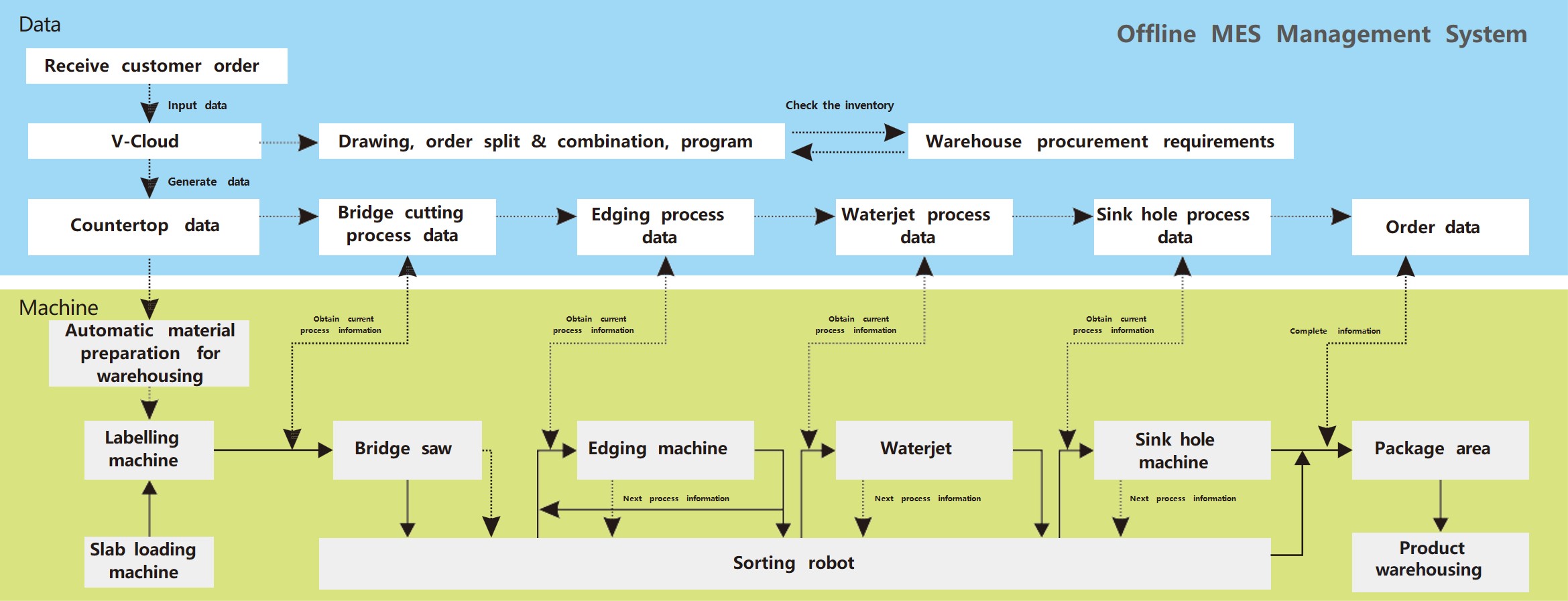

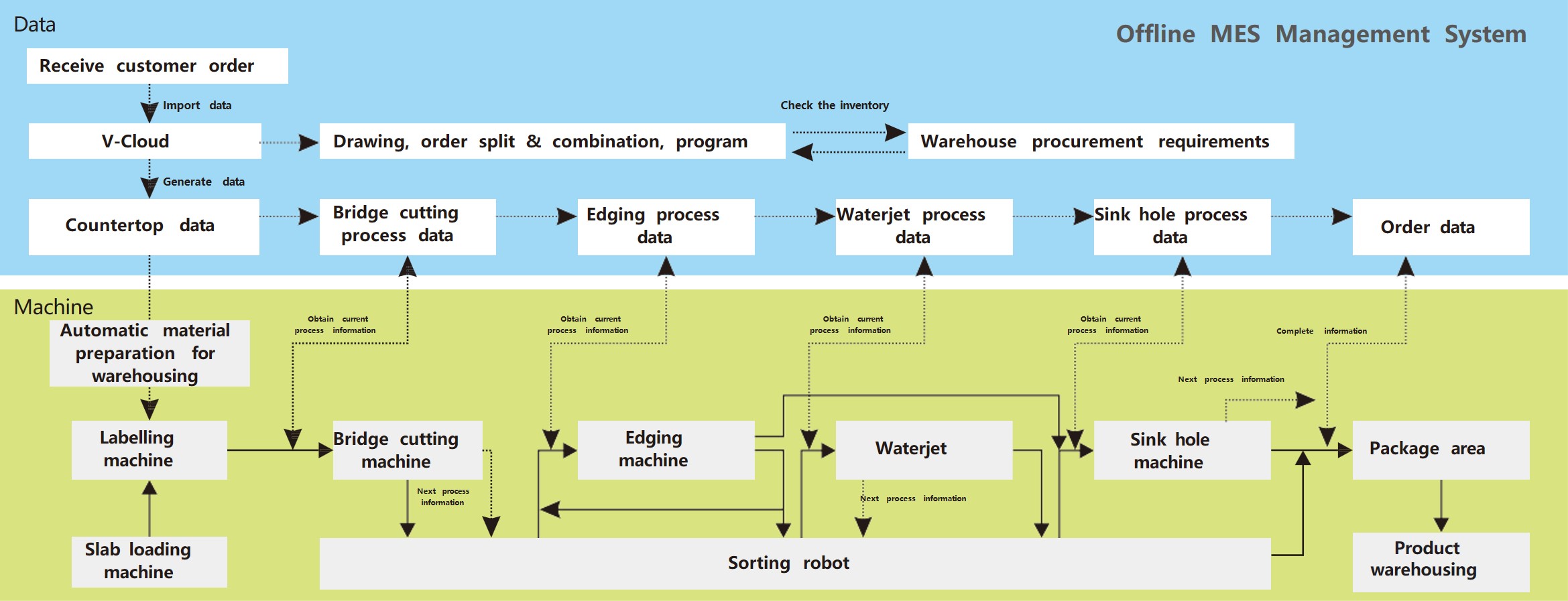

- Veegoo's intelligent countertop fabrication line revolutionizes the traditional single-machine workstation model by adopting a connected line working method. The line features a high level of automation, with automatic transmission of processing procedures and intelligent sorting and transfer, significantly reducing manual labor. Optimal equipment is used for each process.

- The entire line uses a self-developed platform system and MES system to achieve human-machine collaborative production.

- The production line is suitable for both stone and porcelain slab countertop fabrication, enhancing the versatility of the line.

- Information management is achieved through a software control system, which monitors and manages information in real time, improving production management and quality control.

- By adopting automatic programming combined with manual adjustment, the material yield rate is increased to 85-90%, reducing the generation of waste materials, which meets the requirements of green and environmental protection.

- From the platform system to the MES system, it can be highly customized according to customer needs.

- Equipped with a material preparation system, which can prepare materials in advance according to order.

- Equipped with a residual material management system, which prioritizes the selection of available residual materials during programming and material preparation to improve material yield.

Fabshop Solar

Fabshop Solar is a lightweight production line, which is suitable for small and medium-sized Fabshop. It establishes a complete connection mode that covers the entire process from sales, warehouses, design offices, production workshops to the finished products being dispatched out of the warehouse.

- The production line utilizes a self-developed platform system and MES system to achieve human- machine collaboration in production.

- The production line can fabricate both stone and porcelain slab.

- Information management is implemented through a software control system, enabling real-time monitoring and management of production line, enhancing production management and quality control levels.

- With intelligent program and manual adjustment, it can improve the output percentage and reduce waste material.

- Both the platform system and the MES system can be highly customized according to customer requirements.

Fabshop Galaxy

Fabshop Galaxy is a high-configuration production line, which is suitable for high-output Fabshop. It establishes a complete connection mode that covers the whole process from sales, warehouse, design office, production workshop to the delivery of finished products.

- The production line utilizes a self-developed platform system and MES system to achieve human- machine collaboration in production.

- The production line can fabricate both stone and porcelain slab.

- Information management is implemented through a software control system, enabling real-time monitoring and management of production line, enhancing production management and quality control levels.

- With intelligent program and manual adjustment, it can improve the output percentage and reduce waste material.

- Both the platform system and the MES system can be highly customized according to customer requirements.

Remote drawing in the data center, order decomposition, production scheduling, and materials preparation information

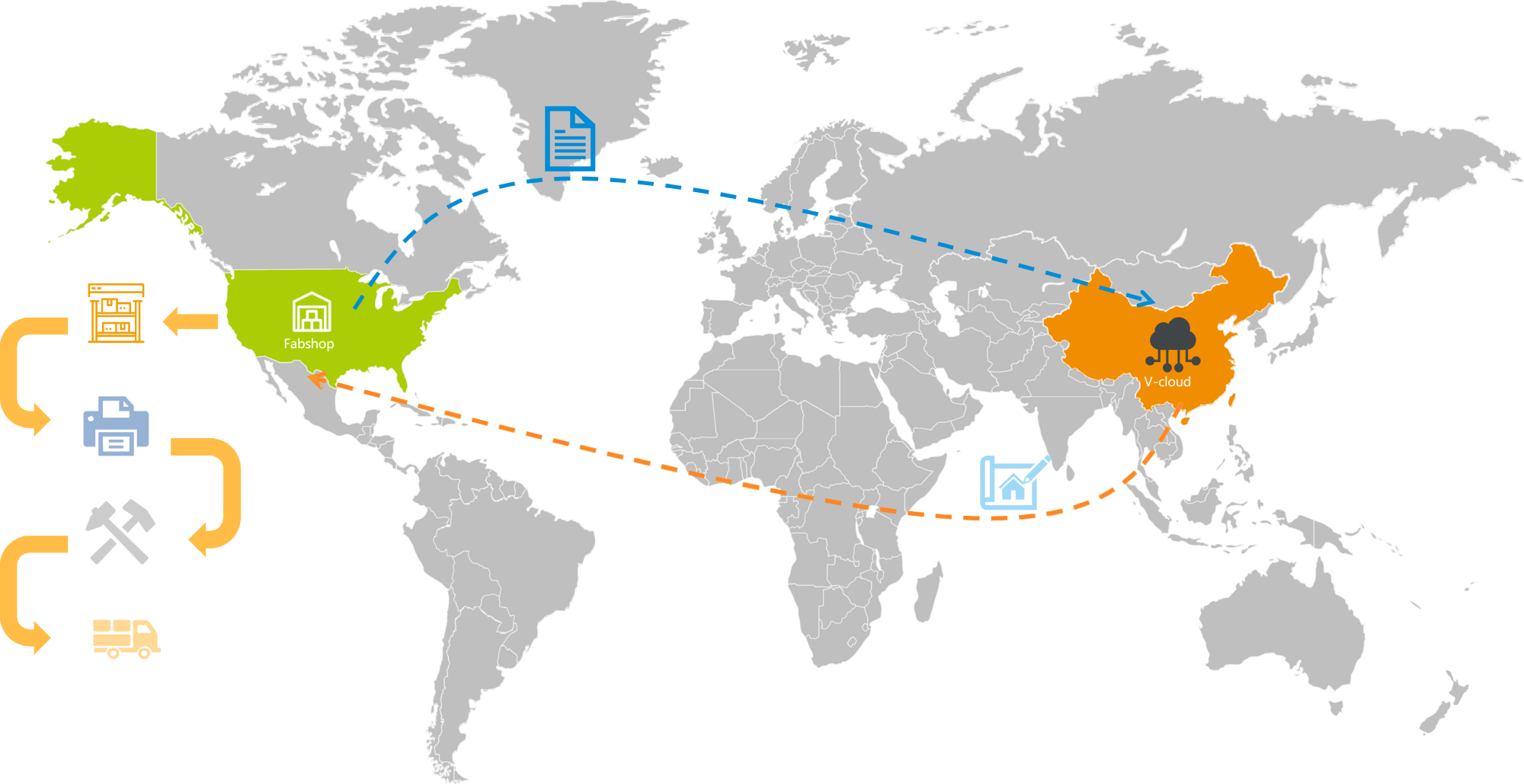

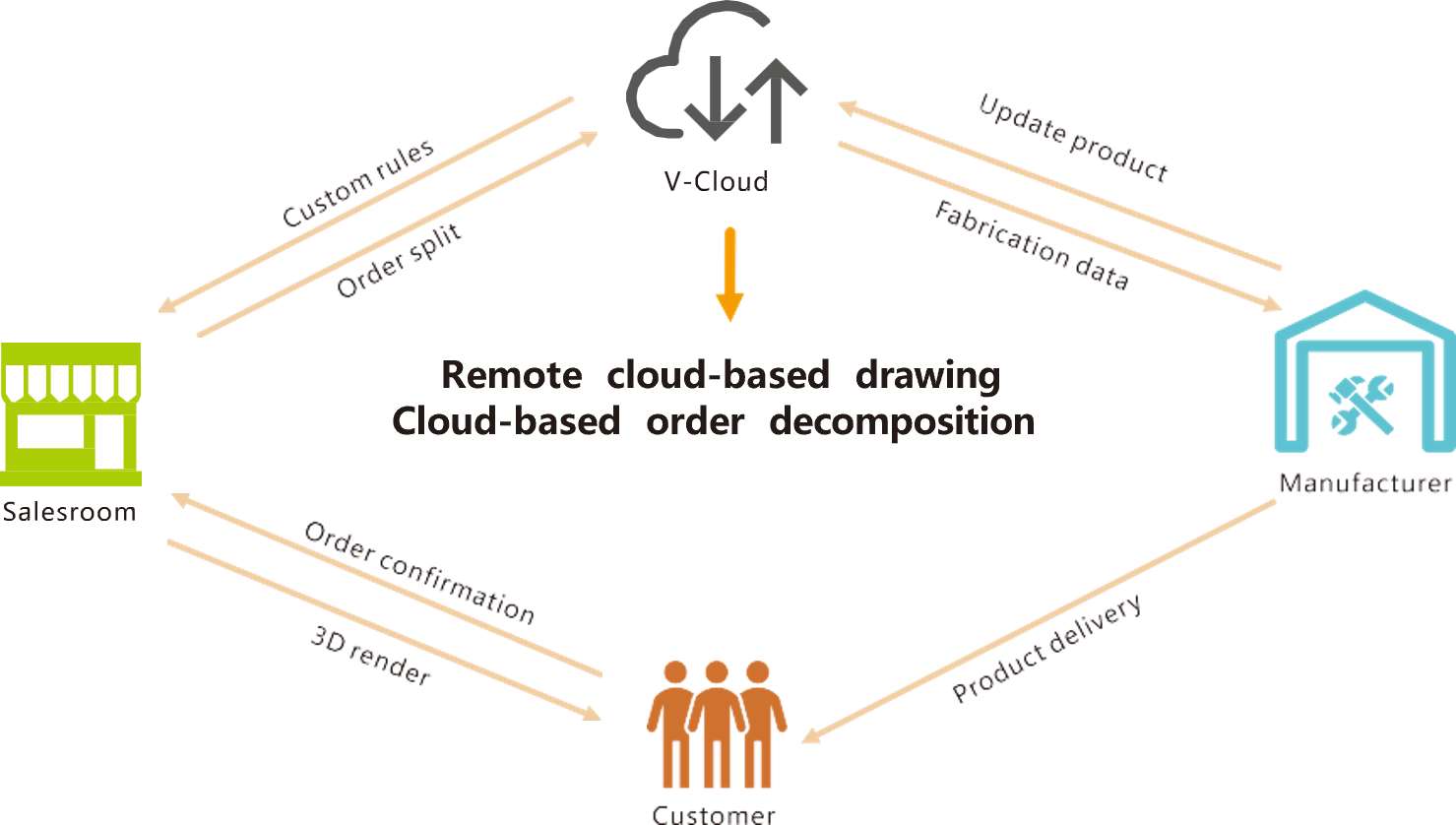

V-Cloud

The entire industry chain is interconnected and integrated, from design in front-end store, taking orders from customer, asking quotes of fabrication, to order understanding in factory, production, fabrication, to product transportation, installation, and delivery.

End-to-End sales solutions

Store all home decoration elements (cabinets, bathrooms, doors and windows, etc.), material and process requirements, and other data in the design database. Designers only need to select from the database to maximize the stability of production.

The designed drawings are sent to the fabrication factory, and the factory knows the designed materials and fabrication processes based on the material and process requirements in the database. This can connect the store with the fabrication factory so as to have smooth, precise and efficient communication.

System Advantage

Standardize the material and fabrication processing constraints for customized design of the store, allowing fabricators and designers to connect at both ends, providing a smooth channel for home customization, and seamless integration between sales and fabrication factories.

- Store customers: What you see is what you get.

- Store design: Lowering the threshold for designers, designers only need to focus on design without considering craftsmanship

- Fabrication end: reduce communication costs, reduce production costs, and ensure set completeness.

Columnar Robot

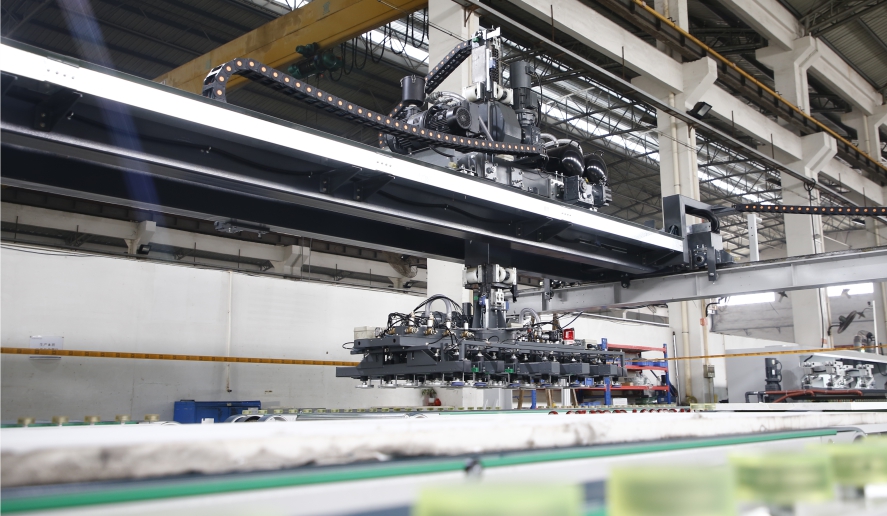

Gantry Robot

Sorting Robot

- The equipment can be applied to various sorting scenes, meeting a wide range of application.

- The equipment has been upgraded with an intelligent operating system, allowing the robot to automatically perform grabbing and transfer slabs, thereby improving production efficiency.

- The main body of the equipment is welded with large size structure, featuring a wide roller span and strong load-bearing capacity.

- The equipment can accommodate different sizes of slabs, improving adaptability and flexibility.

- Through a self-developed platform, it can achieve automatic monitoring with a high degree of intelligence, enabling digital and automated management.

Technical parameters

- Max. size of slab: 3,100X1,600X 40mm

- Min. size of slab: 500X500X10 mm

- Min. width of strip: 100x3,000 mm

- Max. weight of slab: 500 kg

- Average work cycle time about: <1 minute

- External dimensions: 13,000X9,450X4,400mm

- Power: 34KW

- Maximum three-axis speed

- Max. X-axis speed: 50 m/min Max.

- Y-axis speed: 48 m/min Max. Z-axis

- speed: 5.6 m/min

Single-arm labeling machine

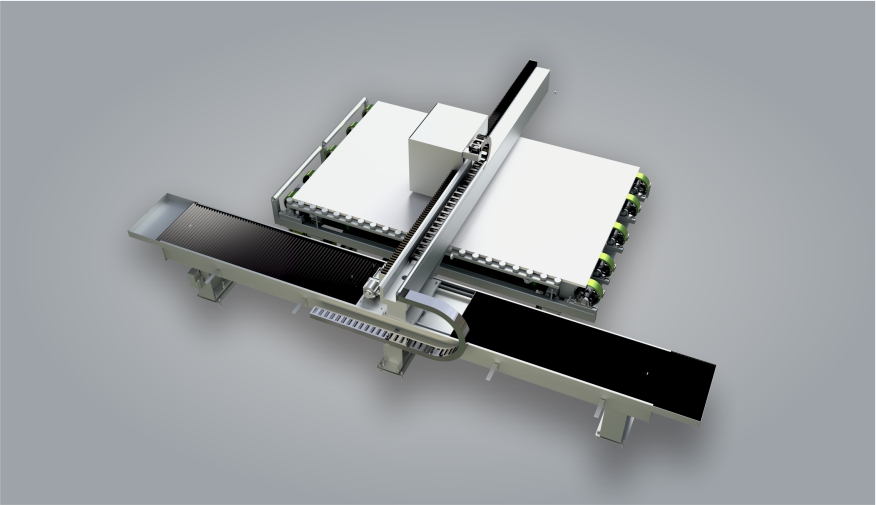

Gantry labeling machine

Labeling machine

- The equipment is configured with servo motor and linear guide rails, enabling fast movement and precise alignment to improve labeling efficiency.

- The equipment is equipped with CNC control system and detection switch to ensure accurate movement and enhance the accuracy and reliability of labeling.

- The equipment supports the OPC UA communication protocol, allowing remote monitoring of the device through computer, to achieve intelligent management.

- The main body is welded with profiles, providing stronger load-bearing capacity to ensure the stability and reliability of the equipment;

- The equipment can be integrated with different equipments and supports customized design for labels.

- Through a self-developed platform, it can achieve automatic monitoring with a high degree of intelligence, enabling digital and automated management.

Technical parameters

- Slab width: 500-1,600mm

- Slab length: 1,000-3,100mm

- Slab thickness: 10-40mm

- Transmission accuracy: ±2mm

- Installed power: 3.8KW

- Labeling size: QR code

- Positioning speed: 50m/min

- Dimensions: 4,500X3,200X1,750mm

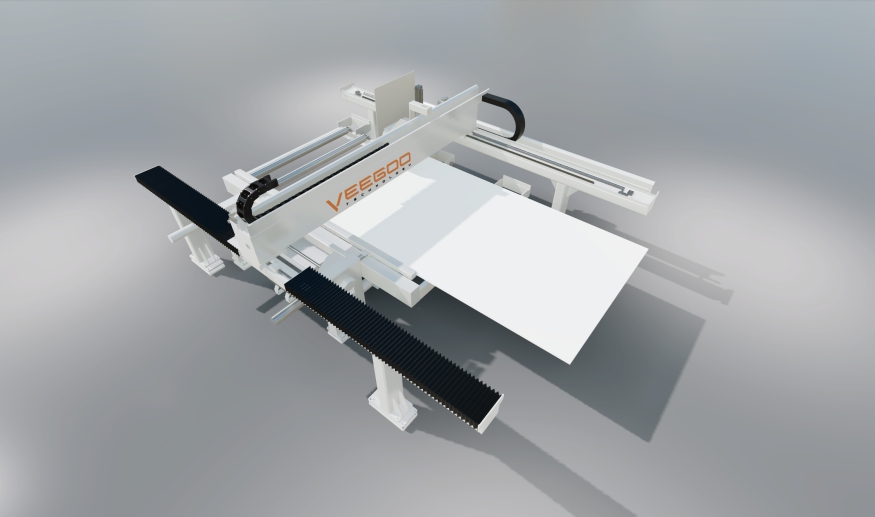

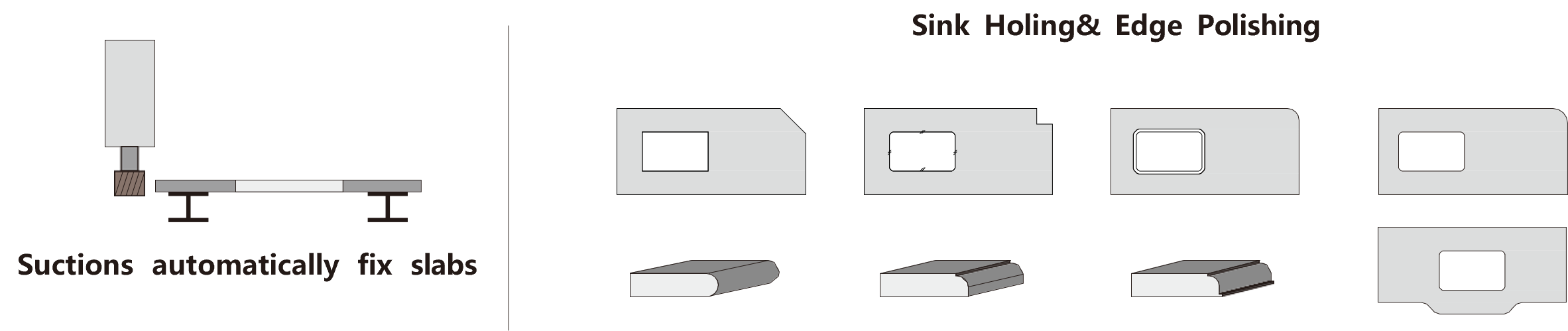

Sink Holing CNC Machine

Sink Holing CNC Machine

Sink Holing CNC Machine

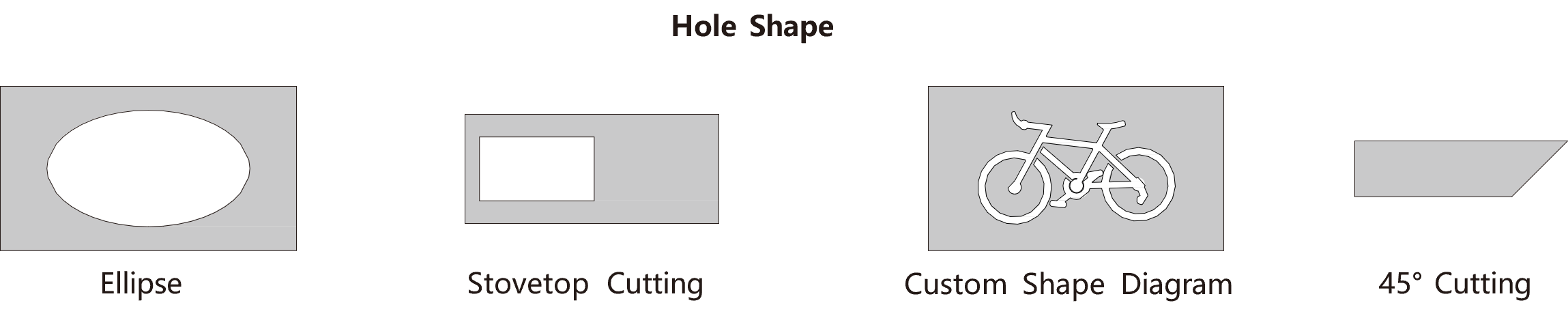

The Sink holing CNC machine is used for excavating holes in countertop panels, rough grinding, fine grinding, and rounding the outer fillets. It is equipped with an automatic tool changer magazine that can accommodate up to 20 cutting tools at most. It can automatically change tools to quickly complete processes such as excavating holes for square and round basin holes, polishing, and rounding the outer fillets. The automatic adjustment range of the width of the panel is 500-1,000 mm.

- The equipment can achieve the following functions: automatic tool change, automatic synchronous belt lifting, automatic slab loading and unloading, and etc., which can quickly finish processing and improve production efficiency.

- The equipment has a new function of automatic width adjustment, which improves the accuracy of slab processing.

- The equipment can adapt to the processing of slabs with different sizes.

- The equipment is made of high-quality steel and equipped with a new water-cooling spindle, making it more stable and reliable, and reducing operating costs.

- Through a self-developed platform, it can achieve automatic monitoring with a high degree of intelligence, enabling digital and automated management.

Horizontal Edge Polishing Machine

Vertical Edge Polishing Machine

Countertop Edge Polishing Machine

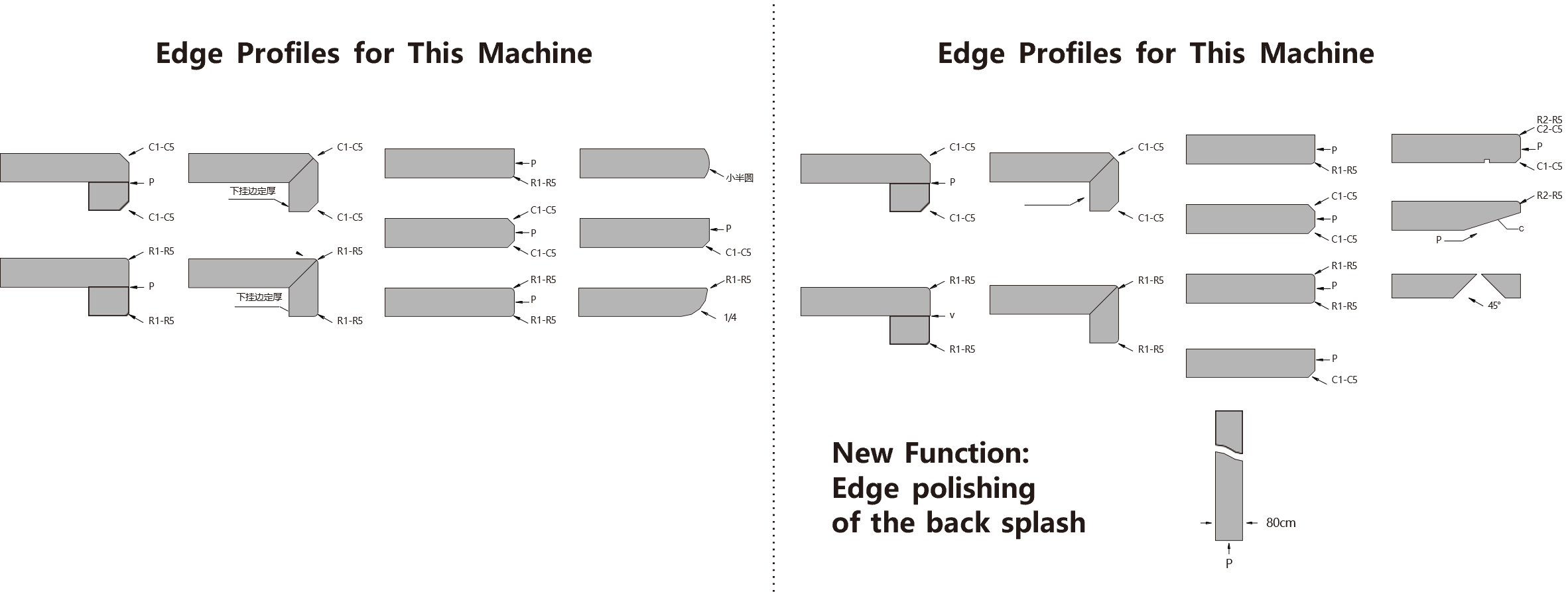

Countertop Edge Polishing Machine is suitable for polishing natural stone, engineered stone, porcelain slabs, straight edges, and rounded corners and beveled edges.

Caltilever Water-jet Cut

Gantry Water-jet Cut

Water-Jet Cut

The water jet cutting technology is widely used in the fabrication of porcelain slabs, such as basins for porcelain slab washstands, under-box hole cutting, porcelain slab tea tables, and porcelain slab kitchen countertops. The water jet cutting platform is made of double-layer 6mm steel plates welded together, which ensures stability and durability.

Key components such as the ball screw and intensifier are made of imported materials, resulting in a longer service life. The five-axis cutter head is equipped with a waterjet cutting system, achieving higher cutting precision, and its cutting speed is leading in the same industry.

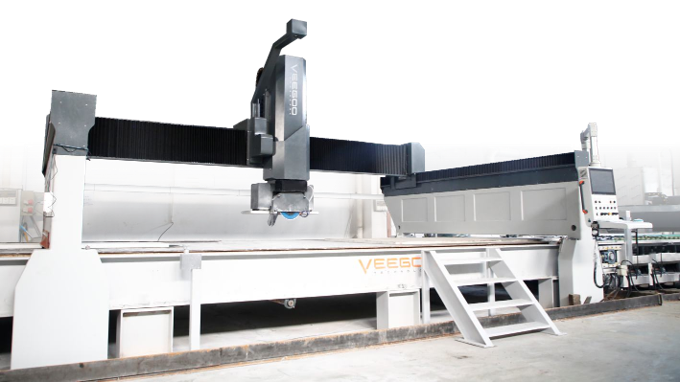

Multi-Functional Five-Axis Bridge Cutting Machine

Multi-Functional Five-Axis Bridge Cutting Machine

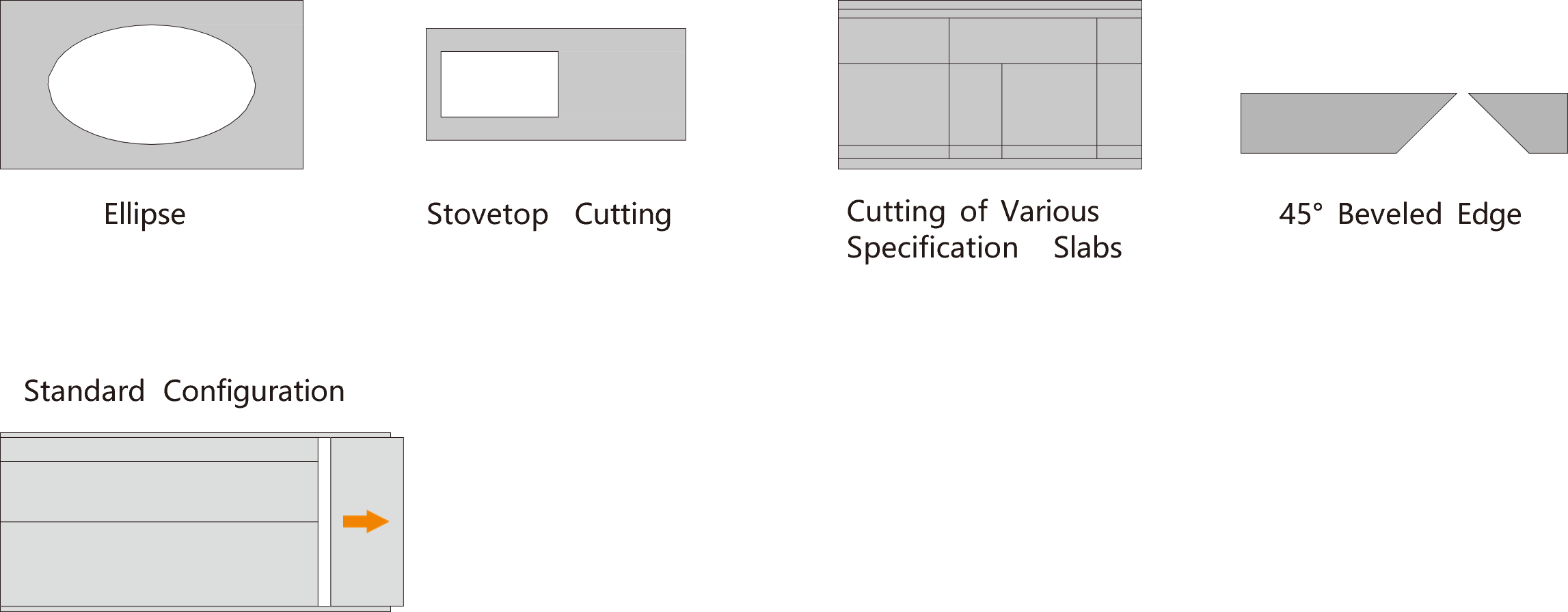

This machine is an integrated Multi-Functional five-axis bridge cutting machine, designed for cutting and profiling various shapes, including standard slabs and irregular forms (such as curved lines, straight lines, irregular lines, villa window lines, garden arc slabs and garden square inlays, etc.). It offers several advantages, including high cutting speed, low processing cost, high cutting accuracy, and simple, intelligent operation.

Suitable for cutting and processing various types of stone materials, such as porcelain slabs, marble, engineered stone, quartz and granite, this machine is the preferred choice for stone processing enterprises in construction, landscaping, and artistic processing.